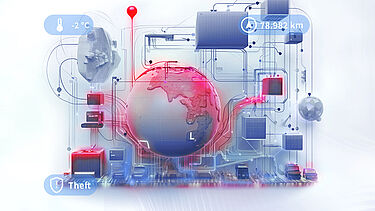

Optimise your construction machinery fleet without retrofitting telematics devices.

Use the AEMP 2.0 interface to receive machine data directly from the manufacturer and display it in our COMMANDER.

Manufacturers of construction machinery have all the relevant data on their machines, which can often only be recorded by their own sensors. We import the data via the ISO 15143-3 interface without any additional hardware or installation work. When using our COMMANDER telematics software, you don't even realise that the data flows into our system via the manufacturer. You can simply use the system as usual. The manufacturer decides exactly which data can be transferred. Typically, this involves operating hours, idling times, diesel consumption and tank levels.

- Telematics data from different manufacturers in one portal

- Networking with other assets via retrofitted telematics devices